2015-02-16 14:18

Marykay new quality inspection laboratories and R & D building debut

|

CNDSN2 month 16 days [] (xinhuanet.com) Marykay new quality inspection laboratories and R & D buildingdebut -- those security cosmetics quality key details recently, the reporter visited from America world-renowned beauty, beauty makeup brand Marykay is located in Hangzhou City Economic Development Zonewithin the Asia Pacific production center, with the completion of the New Asia Pacific R & D building. The city covers an area of more than 70000, 2000 square metres of "beautiful DreamWorks" built from R & D,manufacturing to quality inspection a full range of quality and safety system, to ensure that each product can meet the quality. Marykay Asia Pacific production center according to FDA GMP standard and America drug China "cosmeticsproduction enterprises hygiene norms" established a set of perfect quality assurance system, carries on the comprehensive control of raw materials, manufacturing process, storage, transportation and laboratory. Theproduction center has passed the ISO9001:2008 quality system certification and ISO14000:2004 environmental management system certification. In 2008, Marykay Asia Pacific production center also hasone through the quality certification bodies the world's most stringent Australian medical suppliesSupervision Bureau (TGA) audit certification. The one hundred thousand level of clean production workshop of industry workshop of pharmaceutical D standard, clean system per hour, 15 times the air renewal, to ensure that products from bacterial invasion in the production process, so as to achieve stable quality. - into the clean work area need to arm guards, staffneed to change after disinfection work shoes, put on work clothes and take conjoined isolation, masks, the key hair sets and goggles quality control: a comprehensive testing requirements and high precision to ensure the quality such as a laboratory.

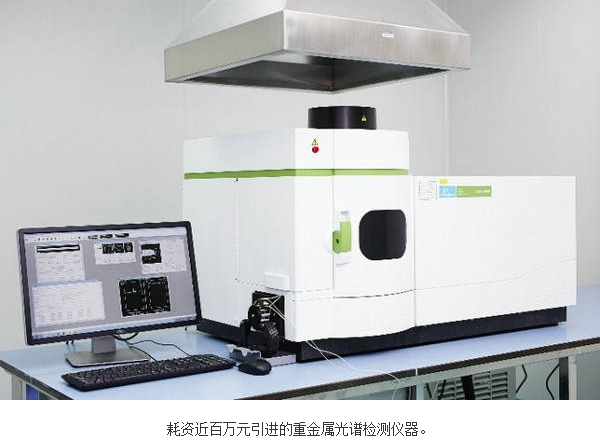

New quality test center at a cost of nearly twenty million yuan to build, set up in Marykay Asia Pacificproduction center, completed the upgrade to the 14 end of the year. 4 kinds of high precision laboratorythrough a comprehensive inspection to ensure each component of product can meet, and even higher than the national standard of correlation detection. In order to obtain a stable effect, all the product formula in the research and development phase are required to undergo 64 weeks, up to 448 days component stability test, constant temperature box usingprofessional simulation 45 degrees, -15 degrees and high low temperature cycle conditions, to ensure that the products can also play the best efficacy in extreme conditions. The test microorganisms in the laboratory to ensure that the products can feel at ease to use in the warranty period, to avoid the product deterioration. As the domestic minority several are less comprehensive inspection of all raw materials, packaging materials, semi-finished products, finished products cosmetics company, Marykay each batch of semi-finished products must get in quality report complete before it can enter the finished filling link. Good night cream to magic as an example, from raw materials to finished products to finished half filling need to experience the appearance inspection, physical and chemical detection, detection, detection of content of active substance of preservatives, heat / cold detection, detection of microorganism and hundreds of othertest items. The foundation of good quality control, raw materials: raw material is the first step, quality of chain inMarykay, each batch of raw materials into the factory, are to physicochemical and microbiological analysis of all indexes. This cost nearly one million yuan to introduce heavy metal detection instrument with highprecision and accuracy, and can prevent the raw material containing heavy metals or regulations for restricted substances risk.

Take use of semi finished products from raw materials to finished production, filling, the entire productionprocess control by the bar code recording, to ensure that every link is accurate, so that each product can betraced to specify a batch of raw materials as well as all the circulation link. Quality as a source of 360 degree production quality management, when the magic new moisturizing skin water irrigation automatic packing production line adopts Germany imported filling technology, Nissan canexceed one hundred thousand bottle. As the economic development zone of Hangzhou industrial tourism,visualization "Transparent Factory" design by Marykay Asia Pacific production center, can see the whole process of production through a long visit to the gallery. "Safe, stable, reliable" is manufacturing the highestcriterion. Marykay Asia Pacific Production Center unveiled for the first time, a new Marykay Asia Pacific R & D center,in addition to do feasibility study for technology transfer and new technology localization, will be China and Asia Pacific area of new products to market and provide stronger support. * (original title: Marykay new quality inspection laboratories and R & D building debut) Editor: small Shen |